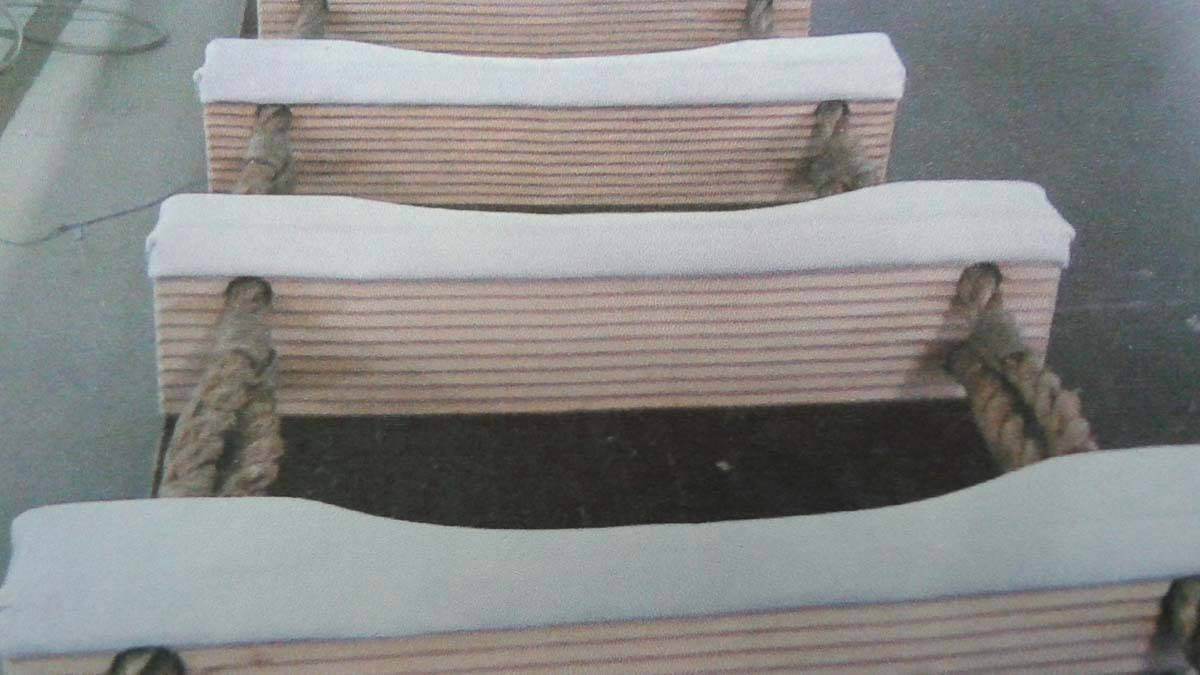

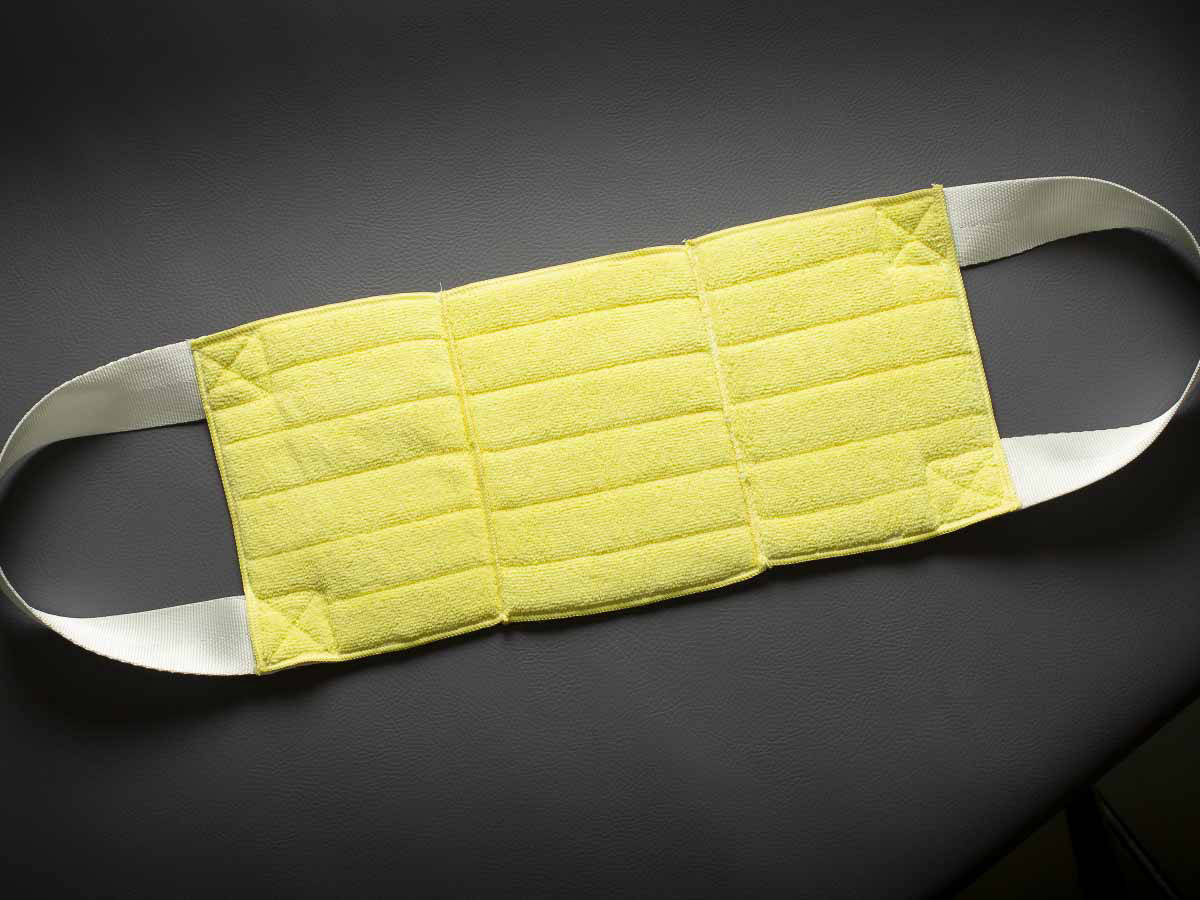

Whether it’s steel-wire ropes, fiber ropes, chains or textile straps, we manufacture load harnesses and lashing goods for customer-specific use. Lifting and lashing, these are basics in rigging.

The use of high quality materials is essential in shipping and industry. We know the required materials in all their forms and know about their specific properties, and applications.

Carrying capacity, corrosion and elasticity: the products that we consider in the planning and manufacturing of our products. Safety has the highest priority in all cases.

Our customers can always rely on our commitment and our craftsmanship. We are used to deliver in time and professionell Installation on site.

Working in our rigging loft means traditionell craftmanship like: hand splicing, mechanical splicing (pressing), sweating wire rope sockets, and swaging terminals.

Our expertise is in demand both in production and in cooperation with our customers. We would be happy to discuss with you the question of whether chains, fiber ropes or steel-wire ropes are more suitable for the respective area of application.

We assemble the following ropes, chains and nets at the customer's request for various types of ships: